IIOT: Industrial Internet of Things

Have you ever thought if automation will take over industrial processes over time?

In India, 51.8% of industrial processes are automated and are increasing with time.

Automation and Internet Cloud Computing are evolving and merging into a space allowing for Artificial Intelligence or AI programming to facilitate improvements in productivity and efficiency with many economic benefits. Along with AI and ML and other advancements with the internet, we are reaching the next industrial revolution, mining and turning data into information.

This period of revolution is called Industry 4.0 or the fourth Industrial Revolution, which includes the Industrial Internet of Things (IIOT) and Digital Transformation mechanisms. In short, a period of automation.

Let us learn more about this fascinating technology known as the Industrial Internet of Things or IIOT.

These innovations envisage solutions to new challenges and possibilities.

A brief overview of Industrial IoT

The IIOT or Industrial Internet of Things or Industrial IoT is the extension of the Internet of Things (IoT) across several industries such as manufacturing, logistics, and healthcare. This trend of automation and data exchange is known as Industry-4.0.

IoT is the profession of objects such as cars, home appliances, and devices that connect the physical world to the digital world. This technology enables humans to interact with these devices to gain benefits, and improve their consumer experience and convenience.

An example of this would be connected home appliances that can reduce your monthly bills. This device will automatically turn off the electricity by either managing resource usage when you leave home or adjusting the room temperature basis on weather conditions.

Another example of this is google nest which aims to create a more thoughtful home. This example of home automation is a programmable thermostat that learns what temperatures you like, turns itself down when you are away, and is easily controllable from anywhere over wifi.

IoT, IIOT, and Industry 4.0

The Internet of Things (IoT) is the network of connected technologies and things that helps in connecting and exchanging data with other devices and clouds over the internet.

The industrial internet of things (IIoT) is the extension and usage of the internet of things (IoT) in industrial sectors such as manufacturing, automotive, etc.

Industry 4.0 is the current revolution of automation and data exchange in manufacturing technologies. It includes cyber-physical systems, IoT, cloud computing, smart factories, and predictive analytics.

In simple words, Industry 4.0 circumscribes IIOT.

Industry 4.0 is about executing the IIoT, AI/ML, real-time condition monitoring, and usage of IT and telecommunications advancements to achieve faster and more efficient production.

Talking about IoT and IIOT, the only difference is their general usage.

IIOT is mainly involved in commercial usage, while IoT is used for industrial purposes, such as manufacturing, automotive systems, and management sectors.

IIOT uses more sensitive and precise sensors, including more locations where technologies on the supply chain side with more sophisticated advanced controls and analytics.

Both IoT and IIOT are communication-based ecosystems, but IoT is intended exclusively for household usage in the commercial sector, while IIOT pertains to the industrial sector.

IIOT deals with connectivity for smart factories, machines, energy systems, management, and more to streamline business operations. It has led to innovations like the smart factory and virtual manufacturing.

The main differences between IoT and IIOT also include the scale of operation and volume of data gathered.

IoT generates medium or high volumes of data, while IIOT generates a massive amount of data.

It includes big data, cloud computing, artificial intelligence, machine learning, cloud computing, and cybersecurity as necessary computing requirements.

Some more examples are drones to monitor oil pipeline sensors to monitor smart factories’ drilling equipment excavators, earthmovers, tractors, and sprayers in agriculture.

In case of failure, IOT consumer-level devices have a low risk of impact as the breakdowns do not immediately create emergencies. While, IIOT connects critical machines and sensors in high-stake industries such as aerospace, defense, healthcare, and energy. In case of failure, these system failures result in life-threatening situations.

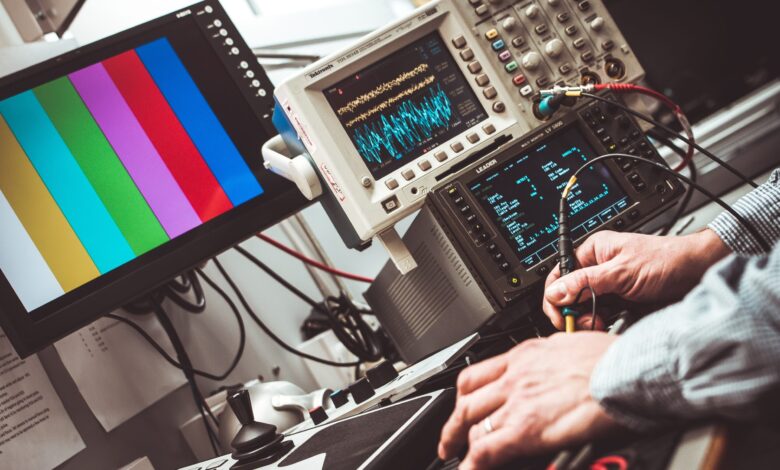

Technologies used to enable Industrial IoT

Industrial IoT depends on many technologies such as Artificial Intelligence, Cyber Security, Cloud Computing, Edge Computing, and Data mining.

Let us understand each of these in detail:

Artificial Intelligence

IoT is the concept that enables communication of everyday physical objects directly with the internet. Artificial intelligence involves the creation of machines to do intelligent things without any human intervention.

The combination of AI (Artificial Intelligence) and IoT is making us reassess the way industries function.

AI-enabled IoT helps in the creation of intelligent machines. These machines simulate smart behavior and support decisions without any human interference.

Cybersecurity Technology

Cybersecurity technology is a predominant platform for IoT and IIOT that helps in enabling disconnected machines to connect and communicate in an efficient and secure method.

Cybersecurity plays a crucial role in maintaining the security of devices- hardware, software, and connectivity. It helps in making everything secure for the efficient working of IIoT objects.

Without cybersecurity, any hardware or software – from smart TV to alarms, can be hacked. Once hackers gain control, they can usurp the object’s functionality and also invade privacy and get access to the user’s data.

Cloud Computing

Cloud Computing uses IT services and enables the files to be uploaded and downloaded from internet-based servers instead of extranet-connected servers.

It also helps companies to store and manage data over cloud platforms. It also helps in providing scalability in the delivery of applications and software as a service.

At the basic level, IIOT is a way of collecting and analyzing inaccessible data within an inflexible data stream. Cloud computing helps enterprises in the management and analysis of this data efficiently.

For example, Smart TVs and watches now run on the internet, which was lacking earlier. It is known as the Internet of Things, and the application of integrated industrial equipment is IIoT.

Edge Computing

Edge computing is a distributed computing model bringing data storage closer to the location where it is needed and optimizes sensors, industrial computers, and devices that are part of the IIOT system for publishing and consuming data for faster processing.

Industrial edge computing’s main benefit is to help low latency computing to manufacture facilities. It has resulted in the increased usage of edge computing in IIoT devices.

Apart from this, industrial edge computing also helps in enhancing IT security, automating maintenance procedures, and driving automation to the last mile.

The availability of edge devices has made life easier!

The data gets transmitted quickly with much more room for faster actions.

For example, tracking the status of a machine or part of a machine could be done much easier now with high speed. Predictions become easier. BI decisions can arrive at a faster pace.

Data Mining

IoT generates a massive amount of data, which is of great help to stakeholders in making crucial business decisions.

Data mining and analytics are about collating and examining large amounts of data stored from various parts of the enterprise. It plays a crucial role in uncovering potentially useful patterns from large data sets and applying algorithms to extract the hidden information.

With more and more devices connected to IoT, the latest algorithms must be applied to analyze a large volume of data.

Conclusion

So, are you ready to accelerate your IIOT journey?

The future of IIoT Industry 4.0 – the fourth Industrial Revolution.

No matter in which phase you are on your Industrial Internet journey, industrial software can make your business grow exponentially by delivering advanced business solutions at a phenomenal pace.

Empower today’s modern industrial technologies, become more successful with Industrial AI-based solutions, and make your business solve your toughest challenges by using industrial data.