Revolutionising the Petroleum Industry: Harnessing the Power of APM for Unmatched Efficiency and Sustainability

Introduction to Asset Performance Management Systems

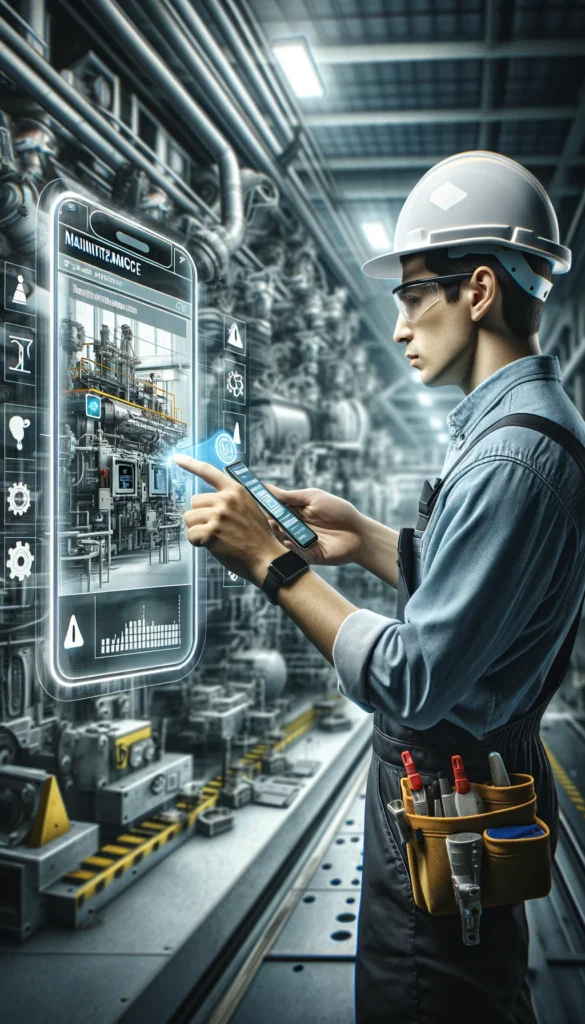

In a world increasingly driven by technology, the petroleum industry stands on the brink of a digital revolution, spearheaded by Asset Performance Management (APM) systems. These systems represent the frontier of industrial innovation, harnessing the power of big data, the Internet of Things (IoT), and artificial intelligence (AI) to transform how assets are managed, maintained, and optimised. APM is not just a tool; it’s a strategic ally in the relentless pursuit of operational excellence, safety, and sustainability. By turning data into actionable insights, APM systems empower the petroleum industry to predict the unpredictable, safeguard the environment, and carve out a path to unparalleled efficiency.

Background: The Evolution of APM

The genesis of Asset Performance Management can be traced back to the industrial age, evolving from simple maintenance schedules to the complex, data-driven systems we see today. Initially, asset management was reactive, focusing on fixing problems as they occurred. The advent of preventive maintenance strategies marked a significant shift, aiming to perform maintenance at predetermined intervals to prevent failures. However, these strategies often led to unnecessary maintenance, increasing costs without significantly improving asset reliability.

The digital era ushered in a new paradigm, characterised by predictive maintenance powered by APM systems. These systems leverage the IoT to collect vast amounts of data from sensors embedded in equipment, which is then analysed using AI and machine learning algorithms to predict failures before they happen. This evolution from reactive to proactive maintenance is akin to the difference between forecasting weather based on historical patterns and using real-time data to predict a storm before it forms.

APM in the Petroleum Industry

In the petroleum industry, where the stakes are high and the margins for error are low, APM systems are nothing short of revolutionary. The complexity and scale of operations, combined with the volatile nature of the market, make efficient asset management a critical challenge.

- Predictive Maintenance: At its core, predictive maintenance through APM involves analysing historical and real-time data to forecast equipment failures. This approach allows for maintenance to be scheduled at the optimal time, minimising downtime and extending the lifespan of assets. It’s a game-changer for the petroleum industry, where equipment failure can have monumental financial and environmental repercussions.

- Operational Efficiency: APM systems offer a holistic view of asset performance across the entire operation, identifying inefficiencies and bottlenecks. By optimizing asset utilization and reducing energy consumption, these systems not only enhance productivity but also contribute to the industry’s sustainability goals.

- Cost Reduction: The financial implications of APM are profound. By reducing unplanned downtime and extending the life of equipment, APM systems can significantly lower operational costs. The savings realized go beyond maintenance budgets, affecting the overall financial health of an organisation.

- Safety and Compliance: The integration of APM systems helps mitigate risks associated with equipment failure, which can lead to accidents and environmental disasters. Furthermore, these systems ensure that operations adhere to increasingly stringent regulatory standards, protecting both workers and the environment.

The Impact of APM

Case Studies /Examples

Case Study 1: Company X’s Offshore Rig Transformation

Background: Company X, a global leader in petroleum extraction, faced frequent equipment failures on its offshore rigs, leading to costly downtime and production losses. The unpredictable nature of these failures made it difficult to plan maintenance efficiently, compelling the company to seek a solution that could predict equipment failures before they occurred.

Implementation of APM: Company X embarked on a digital transformation journey by implementing an advanced APM system across its offshore operations. The APM system was integrated with thousands of sensors placed on critical equipment, collecting real-time data on operational parameters such as temperature, pressure, vibration, and flow rates. This data was then analyzed using machine learning algorithms designed to detect patterns and anomalies indicative of potential equipment failure.

The Incident: Within months of implementation, the APM system flagged an anomaly in the vibration data of a critical centrifugal pump on one of the rigs. The pattern was subtle, yet the system’s predictive model identified it as a precursor to bearing failure, a common issue that could lead to catastrophic pump failure if left unaddressed.

Response and Outcome: Armed with this predictive insight, Company X’s maintenance team was able to plan and execute a targeted maintenance operation. The operation involved replacing the bearings during a scheduled downtime, thereby avoiding an unscheduled shutdown. This proactive approach not only prevented a potential production halt, which could have cost millions in lost revenue but also averted the risk of an oil spill, reinforcing the company’s commitment to environmental sustainability.

Benefits Realized:

- Financial Savings: The intervention saved Company X an estimated $5 million in potential lost production and equipment replacement costs.

- Operational Efficiency: The rig experienced a 20% reduction in unscheduled downtime compared to the previous year, significantly improving its operational efficiency.

- Safety and Environmental Impact: By preventing the equipment failure, the company also avoided the risk of accidents and environmental contamination, underscoring the role of APM in promoting safety and sustainability.

Case Study 2: Refinery Y Enhances Safety and Compliance

Background: Refinery Y, operating in a region with stringent environmental and safety regulations, struggled with maintaining compliance due to recurrent equipment failures. The refinery’s traditional maintenance strategies were proving inadequate in identifying and addressing the root causes of these failures.

APM Adoption: To tackle these challenges, Refinery Y implemented an APM system tailored to its specific needs. The system utilized advanced analytics to monitor the health of assets in real-time, focusing on high-risk equipment such as reactors, heat exchangers, and compressors.

The Challenge: Shortly after implementation, the APM system identified a series of temperature fluctuations in a critical reactor, which were not detected by the traditional monitoring systems. These fluctuations posed a significant risk, as they could lead to overheating and potentially cause a catastrophic event, jeopardizing the safety of the refinery’s operations and surrounding communities.

Proactive Measures: With detailed insights from the APM system, Refinery Y’s engineering team conducted a thorough analysis, which revealed that the fluctuations were due to a partial blockage in the reactor’s cooling system. By addressing this issue proactively, the refinery not only averted a potential disaster but also improved the reactor’s efficiency.

Impact and Advancements:

- Enhanced Safety: The proactive identification and resolution of the issue significantly reduced the risk of accidents, contributing to a safer working environment.

- Regulatory Compliance: The refinery was able to demonstrate compliance with safety and environmental regulations more effectively, avoiding potential fines and legal challenges.

- Operational Improvements: The incident led to a review and enhancement of maintenance strategies across the refinery, leveraging APM insights to prevent similar issues in the future.

Future Outlook: The Evolving Landscape of APM in the Petroleum Industry

The horizon for Asset Performance Management (APM) in the petroleum industry is vast and brimming with potential. As we venture further into the 21st century, several key trends and technological advancements are set to redefine the role and impact of APM systems. Here’s what the future might hold:

- Integration of Advanced AI and Machine Learning: Future APM systems will harness more sophisticated AI and machine learning algorithms, capable of more nuanced predictions and analyses. These advancements will enable even earlier detection of potential failures, further reducing downtime and maintenance costs.

- Digital Twins Become Mainstream: Digital twins, or virtual replicas of physical assets, will play a central role in APM. By simulating the real-world performance of assets under various conditions, digital twins will offer unprecedented insights into asset behaviour, facilitating more precise maintenance and operational decisions.

- Autonomous Operations: The integration of APM with robotics and autonomous systems is on the horizon. This synergy will enable automated maintenance tasks, such as inspections and repairs, carried out by drones or robots, reducing the need for human intervention in hazardous environments.

- Blockchain for Enhanced Security and Transparency: Blockchain technology could be integrated with APM to secure data exchange across the supply chain, ensuring tamper-proof records and enhancing trust among stakeholders. This could be particularly beneficial in regulatory compliance and environmental monitoring.

- Sustainability and Decarbonisation: As the global push for sustainability intensifies, APM will play a crucial role in helping the petroleum industry reduce its carbon footprint. Optimizing asset performance not only reduces energy consumption but also helps in the strategic deployment of renewable energy sources within the industry’s operations.

- Customised and Scalable Solutions: As APM technologies mature, solutions will become more customized to the specific needs of each operation, whether it’s an offshore platform, a refinery, or a distribution network. Scalability will also be key, allowing companies of all sizes to benefit from APM technologies.

Challenges/Controversies Surrounding APM Adoption

Despite the promising future of APM in the petroleum industry, its path is fraught with challenges and controversies that must be navigated:

- High Implementation Costs: The initial cost of implementing APM systems, including the necessary technologies and training personnel, can be prohibitive for smaller operators. This financial barrier could slow down the widespread adoption of APM technologies.

- Data Privacy and Security: As APM systems rely heavily on data, concerns about data privacy and cybersecurity are paramount. The risk of sensitive operational data being compromised could pose significant challenges to the adoption of APM technologies.

- Technological Complexity and Integration Issues: The integration of APM systems with existing legacy systems can be complex and challenging, requiring significant expertise and resources. This complexity could hinder the seamless adoption of APM technologies.

- Skills Gap and Workforce Transition: The shift towards more automated and data-driven maintenance strategies may exacerbate the skills gap in the workforce. Training and transitioning existing personnel to work alongside advanced APM systems will be a critical challenge.

- Reliance on Technology vs. Human Expertise: There is an ongoing debate about the balance between technological reliance and human expertise. While APM systems offer significant advantages, the risk of over-reliance on technology, potentially at the expense of human judgment and experience, remains a contentious issue.

- Regulatory and Ethical Considerations: As APM technologies advance, regulatory frameworks may struggle to keep pace, leading to a regulatory lag that could stifle innovation. Additionally, ethical considerations, especially regarding autonomous operations and job displacement, will need to be addressed.

Navigating the Future

The future of APM in the petroleum industry is undoubtedly bright, with the potential to bring about transformative changes in operational efficiency, safety, and sustainability. However, navigating the challenges and controversies will require a concerted effort from industry leaders, regulators, and technology providers. By fostering collaboration, investing in workforce development, and prioritizing cybersecurity and ethical considerations, the industry can fully harness the potential of APM to navigate the complex landscape of the 21st century.

Conclusion: Revolutionizing the Petroleum Industry through APM

The journey through the intricacies of Asset Performance Management (APM) systems and their transformative impact on the petroleum industry highlights a pivotal moment in industrial evolution. As we’ve explored, APM stands at the confluence of technology, strategy, and sustainability, poised to redefine operational paradigms within the petroleum sector. This conclusion seeks to encapsulate the essence of APM’s role, its accomplishments thus far, and the path it carves for the future of the industry.

A Catalyst for Digital Transformation: Beyond its immediate benefits, APM serves as a catalyst for broader digital transformation within the petroleum industry. It encourages a shift from traditional, reactive maintenance strategies to a proactive, data-driven approach, paving the way for more sustainable and efficient operations. As the industry grapples with the dual challenges of meeting global energy demands and reducing its environmental footprint, APM offers a pathway to reconcile these objectives through technology and innovation.

Navigating the Future: Looking ahead, the future of APM in the petroleum industry is both promising and challenging. Advances in AI, machine learning, and digital twin technologies will further enhance the predictive capabilities of APM systems, enabling even more precise and timely interventions. The integration of blockchain and the advent of autonomous operations will redefine the landscape of asset management, emphasizing the importance of security, transparency, and ethical considerations.

However, this journey is not without its challenges. The high costs of implementation, the complexity of integrating advanced technologies with existing systems, and the ongoing debate between technological reliance and human expertise represent significant hurdles. Additionally, the evolving regulatory landscape and the imperative for cybersecurity and data privacy demand vigilant attention and proactive measures.

Embracing the Future with Optimism: As we stand on the brink of this transformative era, the petroleum industry’s adoption of APM is a testament to its resilience and forward-thinking ethos. By embracing APM, the industry not only enhances its operational efficiency and safety but also contributes to a more sustainable and prosperous future. The journey of APM is an ongoing saga of innovation, adaptation, and continuous improvement, reflecting the petroleum industry’s commitment to excellence in the face of evolving global challenges.

In conclusion, Asset Performance Management systems represent more than just a technological advancement; they embody a strategic imperative for the petroleum industry. By navigating the challenges and harnessing the opportunities presented by APM, the industry can secure its place in a sustainable future, marked by efficiency, safety, and environmental stewardship. The revolution is underway, and the promise of APM is a beacon guiding the petroleum industry towards a brighter, more resilient tomorrow.